The Challenge

3D Printing is growing up, the advent of Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM), has increased the need for a wider range of raw materials. DMLS involves spreading a very thin layer of metal powder across the surface that is to be printed. Additional layers of powder are then applied and sintered, thus “printing” the object one cross-section at a time. In this way, DMLS gradually builds up a 3D object through a series of very thin layers. The SLM method utilizes high-powered lasers which fully melts each layer of metal powder rather than just sintering it. SLM produces printed objects that are extremely dense and strong. As a result, metals and ceramics are experiencing higher demands in 3D manufacturing for their strength and versatility. According to Ola Lyckfeldt of the Swerea IVF, a major Swedish research group focusing on materials development, particle size, particle size distribution and shape are major determining factors of the quality of the raw materials. As 3D printing companies continue to grow their product and technology base, the major challenge will be to reliably source titanium, nickel, aluminum, cobalt, stainless steel and ceramics to meet 3D Printing Specifications.

The Solution

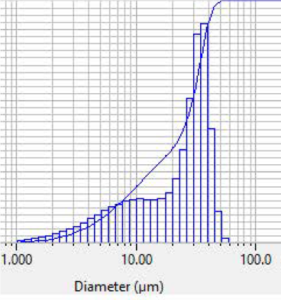

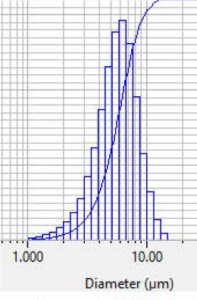

Long standing relationships with material and powder suppliers have allowed Jet Pulverizer to develop best practices around milling, classifying and de-agglomeration of metals and ceramics. Materials come to Jet Pulverizer in a variety of particle sizes, volumes and shapes. They are sometimes pre-milled using hammer mills or ball mills, where their material particle size distribution are relatively flat with far too many “coarse” and a long “fines” tail. (See Figure 1) Each of the additives can be milled in jet mills to single digit microns with very tight PSD. (Figure 2) Jet Pulverizer uses a Horiba LA-960 laser diffraction analyzer in order to perform wet or dry particle size distribution analyses.

Figure 1

Figure 2

Further, agglomeration continues to be a large issue in 3D Printing materials, where the target particle size has been met but the material has clustered which negatively impacts the manufacturers’ applications. Jet mills have proven to help in this regard, the particle on particle collisions taking place inside its chamber allows for a de-agglomeration and smoothing of particles which help flow issues and texture. (Figure 3)

Figure 3